Pulp & Paper Industry

Equipment digitalization in the pulp and paper industry

Pulp & Paper Industry 4.0: Better and more environmental friendly Digitalization

The pulp and paper industry is developing globally, bringing challenges and opportunities to technology suppliers and industry manufacturers. As the market shifts to digital media and internet communications, the market for packaging materials and hygiene-related paper products is growing, while the global market for newsprint is shrinking.

With the intensification of global market competition and policy pressures, markets and consumer demand are adjusting. Therefore, in order to remain competitive, the industry must innovate. The Pulp & Paper industry has great potential for digitalization which will boost productivity and efficiency.

Challenges in the Pulp and Paper Industry

- 01

Market shifting and cost pressure

Profit margins in the pulp and paper industry are very low, and production costs are a key factor in profitability. One way to gain a greater share in the industry is to provide value-added services that competitors cannot provide. Brand owners, who are the ultimate decision-makers on the packaging, want better, faster, more customized products but they do not want to spend more.

- 02

Manufacturing environment control

In the pulp and paper industry, there are many harsh process conditions, such as corrosive pulp that requires extremely high-pressure conditions, with corrosive chemicals, and very smooth and fast rolling operations. Therefore, process control is the key to optimizing plant operation and performance, to carry accurate control and measurement under harsh process conditions.

- 03

Sustainability and environmental challenges

Productivity and profitability under strict environmental guidelines are a unique challenge faced by the pulp and paper industry. The pulp and paper industry are increasingly demanding the reduction of environmental and carbon emissions, and the acquisition of wood is gradually moving to local sustainable sources and recycling. Therefore, it is necessary to develop new technologies to provide the effective utilization of wood and recycling resources, thereby reducing the impact on the environment.

- 04

Equipment stability and performance

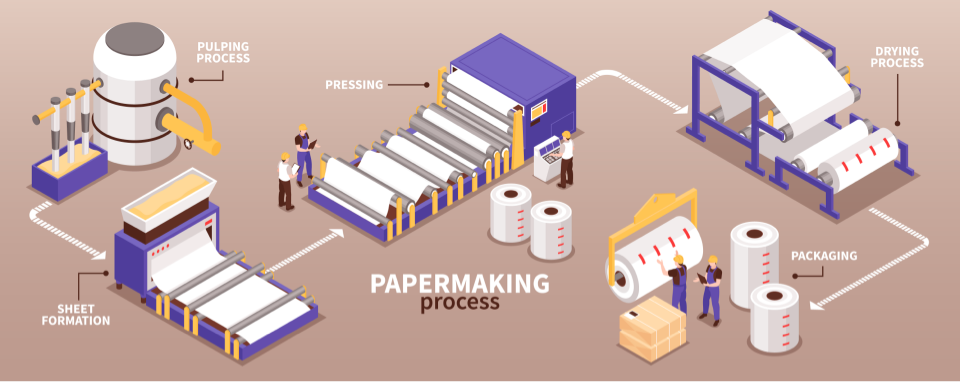

The business of the pulp and paper industry is mainly to use various resources (including wood chips, clay, lime, dyes, chemical resins, and recycled paper) to make wood pulp, paper, or cardboard. The demand for mechanical maintenance is increasing and paper manufacturing, and paper recycling plants also pay more attention to process efficiency and machine reliability than ever before.

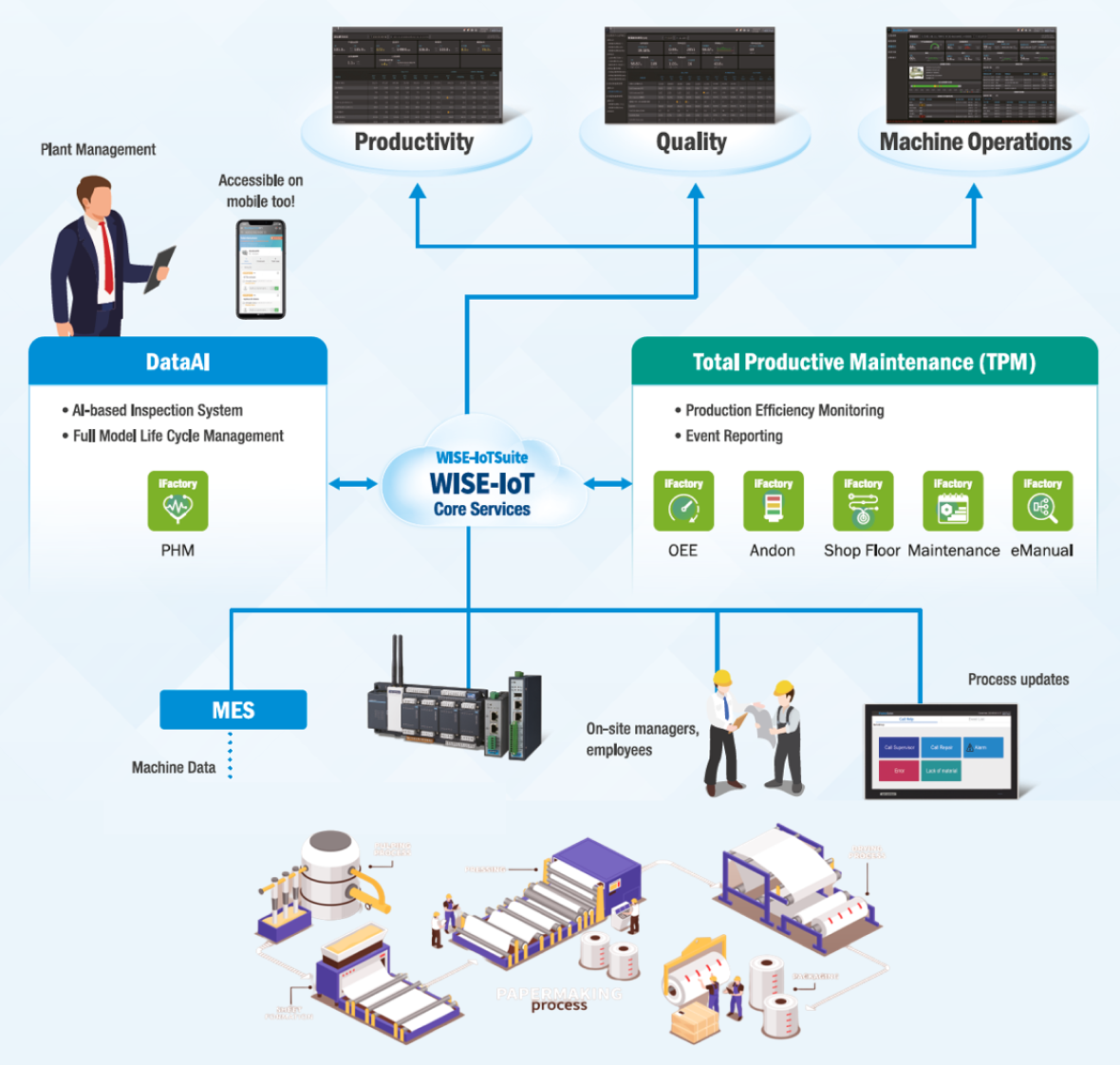

iFactory @ Pulp and Papers

The pulp and paper industry has complex production processes, which can be optimized and digitized through the iFactory Solution suite @ Pulp and Paper Industry. The paper industry, like oil, gas, mining industries, has important asset facilities need to be constantly monitored. Sudden interruption of the production line due to failure will affect the quality and production efficiency.

Advantages

- 01

Safer, connected production

- 02

Efficient energy consumption

- 03

Minimal waste and error reduction

- 04

Increased production efficiency

- 05

Maximized logistical efficiencies

- 06

Assets performance optimization

I.App of the Solution Suite

Overall Equipment Effectiveness (OEE)

Visualized monitoring of OEE indicators and KPIs of the whole plant through data acquisition, aggregation, and machine utilization analysis. Smart factory production efficiency management can be easily realized to increase productivity, review and analysis of major losses, improve equipment utilization, and effectively increase production capacity.

Facility Management & Sustainability (FMS)

Real-time monitoring environmental sensors and track energy consumption of the whole plant by category. Identifies anomalous power consumption with real-time data read by smart meters. FMS allows users to monitor energy consumption information and environment safety, and accurately estimate energy costs. It also optimizes utility efficiency, thereby contributing to business FMS management strategies.

System Architectures of Pulp & Papers Industry

Co-Creation with DFSI

Industrial IoT (IIoT) involves integrating big data, cloud, and AI applications. To embrace this trend, Advantech is collaborating with domain-focused system integrators (DFSIs) to develop industrial apps (I.Apps).

TEXOL Taiwan Link Solutions Co., Ltd

TEXOL, established in 2010, provides a wide range of products and consultancy services with vibration technology as its core. TEXOL focuses on becoming the most professional vibration monitoring solution provider, as well as the provider of equipment vibration predictive and maintenance monitoring solutions,and we strive to create maximum value for customers' products and equipment.

Service RegionsTaiwan, Japan, United States, Thailand

Recommend for you

Software Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE)Visualized monitoring of OEE indicators and KPIs of the whole plant through data acquisition, aggregation, and machine utilization analysis. Smart factory production efficiency management can be easily realized to increase productivity, review and analysis of major losses, improve equipment utilization, and effectively increase production capacity.

Facility Management & Sustainability (FMS)

Facility Management & Sustainability (FMS)Real-time monitoring environmental sensors and track energy consumption of the whole plant by category. Identifies anomalous power consumption with real-time data read by smart meters. FMS allows users to monitor energy consumption information and environment safety, and accurately estimate energy costs. It also optimizes utility efficiency, thereby contributing to business FMS management strategies.