Energy and Carbon Footprint Monitoring in Manufacturing

Maximize Production Efficiency with Minimal Carbon Footprint through FactoryOEE

Elevate Your Manufacturing Operations

To transform factory management by prioritizing energy efficiency, production effectiveness, and carbon footprint reduction, it's a good idea to leverage advanced data analytics. Advantech's iFactory system tracks real-time energy usage for eco-friendly production. Our focus is on creating an application-oriented, efficient, and sustainable factory management tool. Optimize your factory with FactoryOEE for a balanced blend of operational efficiency and minimizing environmental impact.

Elevate Your Manufacturing Operations

To transform factory management by prioritizing energy efficiency, production effectiveness, and carbon footprint reduction, it's a good idea to leverage advanced data analytics. Advantech's iFactory system tracks real-time energy usage for eco-friendly production. Our focus is on creating an application-oriented, efficient, and sustainable factory management tool. Optimize your factory with FactoryOEE for a balanced blend of operational efficiency and minimizing environmental impact.

PLANT APPLICATIONS

INDUSTRY FOCUS Control Energy Consumption

INDUSTRY FOCUS Control Energy ConsumptionEffectively reduces energy consumption by calculating carbon emissions and energy usage for each machine.

INDUSTRY FOCUS Boost Productivity

INDUSTRY FOCUS Boost ProductivityAutomated recording of equipment production enables effective adjustments to parameters and processes, enhancing OEE.

INDUSTRY FOCUS Reduce Ineffective Production

INDUSTRY FOCUS Reduce Ineffective ProductionSwiftly resolve issues, decrease abnormal working hours, minimize waste, reduce manufacturing costs, and boost profits.

Start Your Transformation Journey

Tier-1 EV Thermal Manufacturer Significantly Elevates Overall Visibility in Machine OEE and Facility Energy through Unified IIoT Platform

”We've empowered operators with enhanced insights, enabling swift analysis of production issues and optimized bottlenecks. Freed from paperwork and lengthy communication, they focus on efficiency based on dashboard data. Projections show a 5% quality rate increase and 15% production efficiency rise. Energy monitoring systems have led to 5% energy savings and carbon reduction in 2023, affirming Amulaire Thermal Tech as a Tier-1 supplier with advanced capabilities.”- Production site manager, Amulaire Thermal Tech.

Accelerate Decision-Making Through Generative AI in the EMS Plant

”Factory GenAI saves managers’ time.” The manufacturing manager at Advantech’s SMT plant has been using Factory GenAI for a month and plans to further implement it in the next month to quickly identify and address inefficiencies in production lines, equipment, and work orders, streamlining the entire workflow. The generative AI-powered chatbot assistant delivers real-time alerts and data-driven insights, enabling rapid decision-making, and targeting enhancing productivity by over 25%, reducing downtime by 30%, and boosting utilization rates by 36%.

How FactoryOEE & GenAI help you stay ahead of any situation

OEE Pro | Monitor the real-time status of equipment, machine OEE, carbon emissions, and energy consumption with IoT technology

Features:

• Real-time APQ & OEE analysis

• Energy consumption and carbon emissions analysis

• Flexible custom formulas

Advantages:

• Visibility of energy consumption and carbon emissions of machines and production work orders

• Transparency on equipment efficiency and productivity

• Low-code configuration to quickly setup monitoring and dashboards

Cloud Solution

One-Click Service: Your Gateway to Digital Transformation

• Cost-effective solution with low upfront investment.

• Scalability and flexibility with cloud-based infrastructure.

• Easy to deploy and manage remotely.

| Product Information |

FactoryOEE with WISE-IoTSuite RTM (9803ITEHS00)

• Includes 5 licenses of FactoryOEE cloud subscription for the first year.

• Includes 150 parameters for monitoring OT data. (PLC, sensors, etc.)

On-Premises Solution

Maximize Efficiency: Lightweight, No-Code Embedded Solution

• Robust real-time processing for instant decision-making.

• Enhanced data security within the local network.

• High reliability and stability for uninterrupted operation.

| Product Information |

FactoryOEE with WISE-IoTSuite RTM (9804ENWRK00)

• Works with any Advantech IPC hardware, perpetual license.

• Min. requirements: Intel Celeron / 8GB RAM / Windows 10 or Linux.

• On-prem quick deployment, starting with 5 OEE licenses and 150 parameters.

How can we easily understand the OEE of our factory? Where do we start?

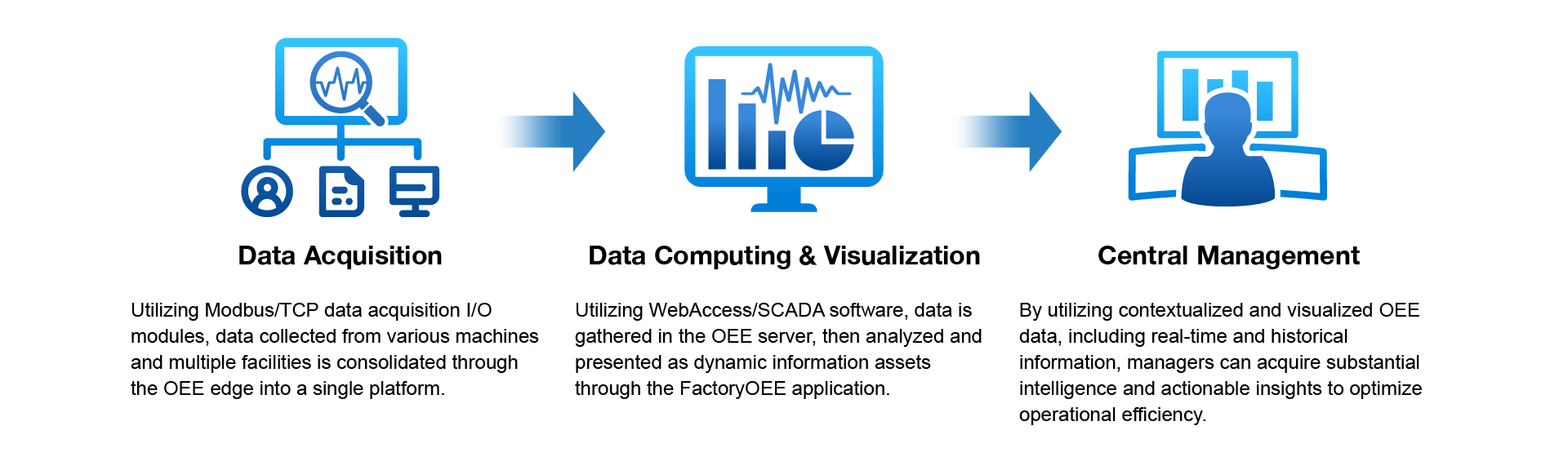

In the digital transformation of enterprises, automation is a pivotal step for enhancing efficiency. However, challenges may emerge. To address this, many adopt OEE automation for real-time insights and optimized production.

In the digital transformation of enterprises, automation is a pivotal step for enhancing efficiency. However, challenges may emerge. To address this, many adopt OEE automation for real-time insights and optimized production.

CASE STUDY Tier-1 EV Thermal Manufacturer Significantly Elevates Overall Visibility in Machine OEE and Facility Energy through Unified IIoT Platform

CASE STUDY Tier-1 EV Thermal Manufacturer Significantly Elevates Overall Visibility in Machine OEE and Facility Energy through Unified IIoT Platform CASE STUDY Maximizing Productivity in the Surface Treatment Industry

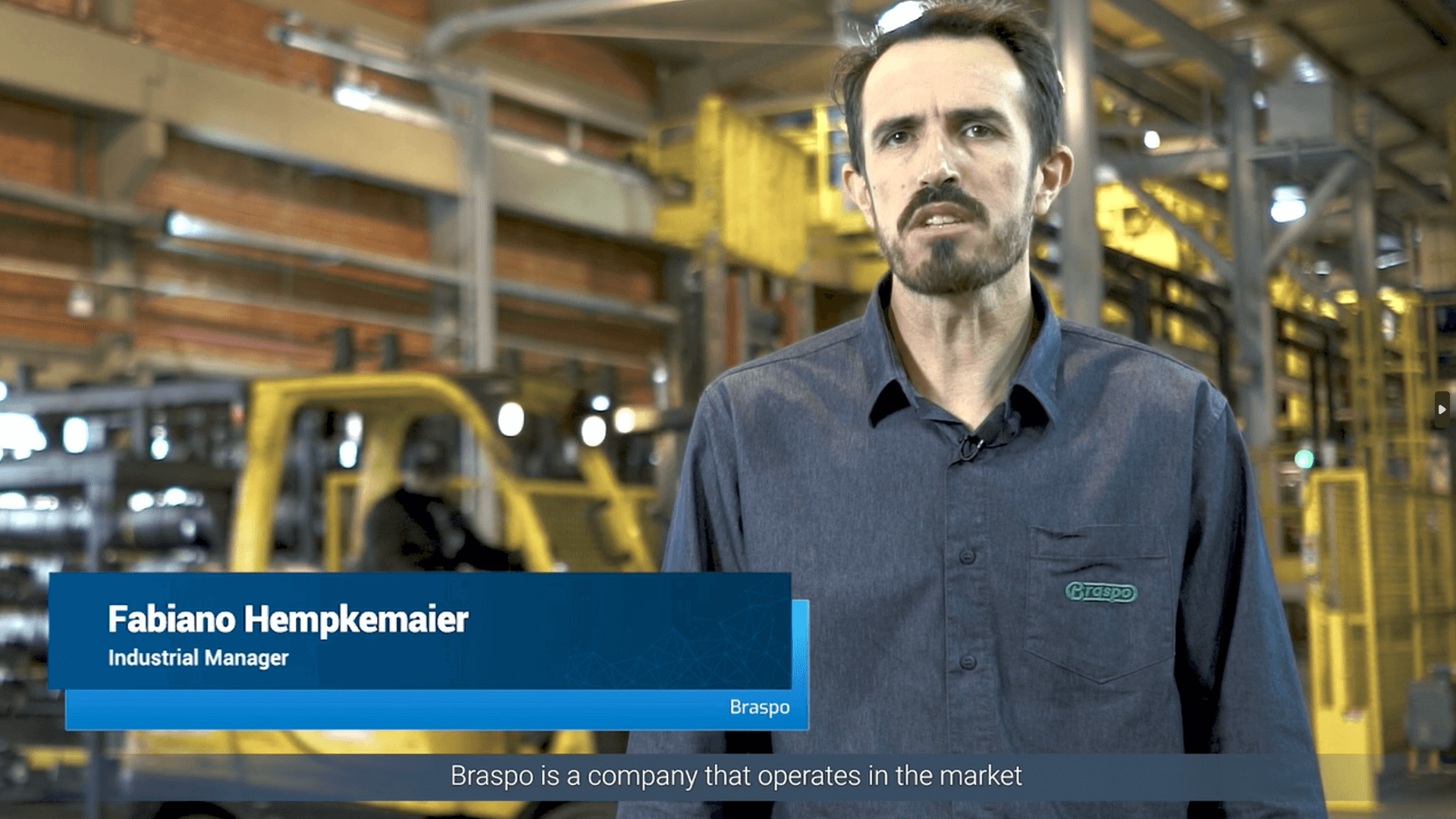

CASE STUDY Maximizing Productivity in the Surface Treatment Industry CASE STUDY Low-Cost Automation and Monitoring in the Die Cast Manufacturing Process

CASE STUDY Low-Cost Automation and Monitoring in the Die Cast Manufacturing Process